Texas' Premier Provider of Overhead, Gantry, Bridge, and Indoor Cranes

Expert Solutions for Industrial and Manufacturing Lifting Needs Across Texas

Comprehensive Solutions for Heavy Lifting

Maximizing Efficiency with Industrial Crane Systems

Expert Solutions for Industrial and Manufacturing Lifting Needs Across Texas

Overhead crane systems offer a range of solutions for moving large loads safely and effectively.

These systems include overhead cranes, gantry cranes, and bridge cranes, each designed for specific applications.

Recent Quotes & Sales

Overcoming Corrosion Challenges in Industrial Crane Systems: A Case Study

Discover how a semiconductor plant tackled severe crane system corrosion. Learn about innovative solutions like the Volley Bus Bar System for harsh industrial environments, and how proper maintenance ... ...more

Crane Quote

September 11, 2024•2 min read

Industrial overhead cranes boost productivity

by freeing up floor space and reducing the risk of worker injuries.

They allow for easy movement of heavy items across facilities, making them essential in many manufacturing environments.

Gantry cranes provide flexibility, as they can be used both indoors and outdoors, and are often portable.

Bridge cranes are valued for their stability and precise load positioning.

They run on elevated rails, offering triple-axis lifting performance.

This makes them ideal for tasks that require careful maneuvering of heavy loads.

By choosing the right crane system, businesses can streamline their operations and improve overall efficiency.

Understanding Different Crane Types

Crane systems come in various designs to handle diverse lifting needs in industrial settings. Each type offers unique advantages for specific applications and environments.

Gantry Cranes: Structure and Applications

Gantry cranes are versatile lifting solutions.

They consist of a horizontal beam supported by legs that move along ground-level tracks. These cranes can be mobile or fixed.

Mobile gantry cranes offer flexibility, allowing for use in different areas of a facility.

Fixed gantry cranes provide stability for consistent, heavy-duty lifting tasks.

Gantry cranes excel in outdoor environments like shipyards and construction sites. They also work well in large indoor spaces such as warehouses and manufacturing plants.

These cranes can lift very heavy loads, sometimes up to several hundred tons. This makes them ideal for handling shipping containers, large machinery, and bulky materials.

Our Industry Standards and Classifications

CMAA standards adherence

Range of capacities (1 to 160 Tons)

Typical ratings (CMAA-Class-D/HMI-H4, FEM-2M/ISO-M5)

Capability for higher ratings (up to Class-E/H5)

| Comparison of FEM, HMI, & CMAA Classifications Class I - Locations |

||||

|---|---|---|---|---|

| Hoist Classification | Corresponding Crane Class | Typical Application | ||

| FEM | HMI | ISO CMAA | DIN 15018 and sim. | |

| 1Cm | H1 | M2 Class A | H1/B2 | Maintenance crane in machine house. Used only occasionally. |

| 1Bm | H2 | M3 Class B | H1/B2 | Light duty work shop crane, single shift operation, low average loads. Maximal load lifted occasionally. |

| 1Am | H3 | M4 Class C | H2/B3 | Light/Medium duty work shop crane, single shift operation, medium average loads. Occasional lifting of max load. |

| 2m | H4 | M5 Class D | H2/B3 | Medium/heavy duty work shop crane, 1 or 2 shift operation. Reular medium and heavy loads. |

| 3m | H4 | M6 Class D | H2/B3 or H3/B4 | Heavy duty crane, 2 shift operation. Nominal load regularly lifted Traverse or other dead loads below the hook. |

| 4m | H4 or H5 | M7 Class D or Class E | H3/B4 or H4/H6 | Very heavy duty crane, 2-3 shift operation, grab or magnet below the hook. Regular heavy loads. |

Overhead and Bridge Cranes: Maximizing Factory Efficiency

Overhead cranes and bridge cranes are crucial for efficient material handling in factories and warehouses. They move along elevated runways, freeing up valuable floor space.

Bridge cranes feature a horizontal beam (bridge) that spans the width of a building. The hoist moves along this bridge, allowing for precise positioning of loads.

These cranes integrate seamlessly with assembly lines and production processes. They can lift, transport, and place heavy components quickly and accurately.

Overhead cranes come in different configurations:

Top-running: The bridge runs on top of the runway beams

Under-running: The bridge is suspended from the bottom of the runway beams

The choice depends on factors like building structure and lifting capacity needs.

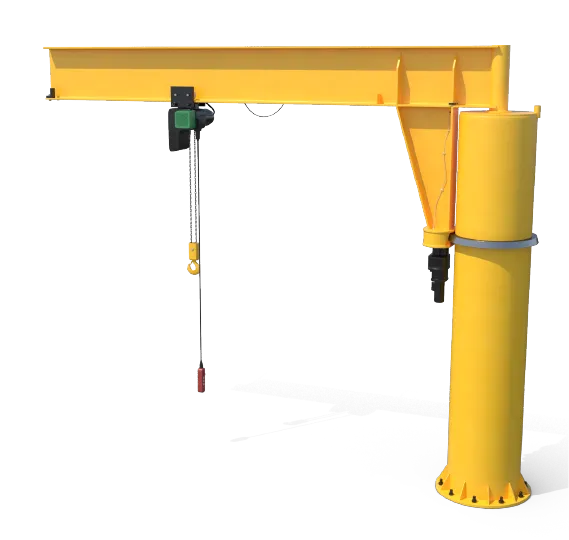

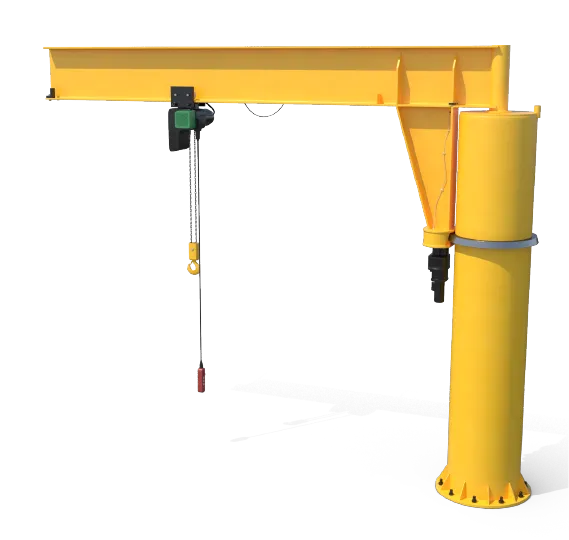

Jib and Monorail Cranes: Versatility in Confined Spaces

Jib and monorail cranes offer specialized solutions for lifting in tight or unconventional spaces. They provide targeted lifting capabilities where larger crane systems may not fit.

Jib cranes feature a horizontal arm (jib) that swings in an arc.

They can be wall-mounted, free-standing, or attached to a column. Jib cranes are perfect for workstations, loading docks, and small workshops.

Both jib and monorail cranes offer:

Precision lifting for delicate tasks

Easy operation in confined areas

Customizable designs to fit specific workplace layouts

Monorail cranes use a single rail system, often following a curved or complex path. They’re ideal for assembly lines or applications requiring repetitive lifting along a fixed route.

These cranes enhance efficiency in specialized manufacturing processes and maintenance operations.

Comprehensive Solutions for Heavy Lifting

Crane design and customization are key factors in creating lifting solutions that meet specific industrial needs. These processes involve careful planning and engineering to ensure optimal performance and safety.

Tailoring Cranes to Operational Needs

Custom-built overhead cranes can range from 20 to 300 feet long with capacities of 5 to over 1,000 tons.

Designers consider factors like lifting capacity, span length, and height requirements.

Single girder cranes work well for lighter loads, while double girder designs handle heavier weights. The choice depends on the facility’s layout and lifting needs.

Customization extends to the crane’s boom, which affects reach and lifting height.

Engineers tailor these elements to fit the specific workflow and space constraints of each facility.

Material and Construction: Ensuring Strength and Durability

Crane manufacturers use high-quality steel in construction to ensure strength and longevity.

The thickness and grade of steel vary based on the crane’s intended load capacity and operating conditions.

Robust construction techniques are employed to create durable cranes that can withstand frequent use.

This includes reinforced welds, precision-machined components, and corrosion-resistant finishes.

Designers also focus on creating maintenance-friendly features.

Easy access to key components allows for efficient servicing, reducing downtime and extending the crane’s lifespan.

Operational Safety and Maintenance

Proper safety protocols and regular maintenance are vital for crane operations. These practices protect workers, prevent accidents, and keep equipment running smoothly.

Implementing Safety Protocols and Standards

Crane operators must follow strict safety guidelines to prevent accidents. They should always check load limits and never exceed them.

Regular inspections are key. Operators should examine cables, hooks, and controls before each use. Any issues need quick fixes.

Training is crucial. All staff working with or near cranes need proper instruction. This includes operators, riggers, and ground crew.

Clear communication is essential. Use standard hand signals or radios to coordinate lifts. Everyone on site should understand these signals.

Personal protective equipment (PPE) is a must. Hard hats, safety shoes, and high-visibility vests help keep workers safe.

Comprehensive Solutions for Heavy Lifting

New technologies are changing how cranes work. Smart systems and better hoists make lifting safer and more efficient. These improvements help factories and warehouses do more work with less effort.

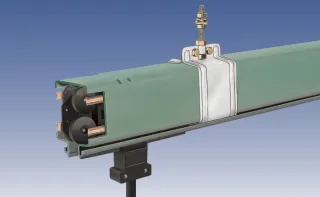

Advancements in Hoisting Mechanisms

Modern hoists have come a long way.

Wire rope hoists and electric chain hoists now lift heavier loads with greater precision.

New drive systems make movements smoother and more controlled.

Improved trolleys allow for better positioning of loads.

This means less time spent adjusting and more time moving materials.

Hoist technology now also includes load sensors that prevent overloading and improve safety.

Automated Crane Systems and Smart Features

Automation is changing the crane industry.

Smart cranes can now follow pre-programmed paths without human input. This leads to faster work and fewer errors.

Remote operation allows one person to control multiple cranes from a safe distance.

This boosts productivity and keeps workers out of harm’s way.

Cranes with cameras and sensors can “see” their surroundings and avoid obstacles.

Some cranes now use artificial intelligence to learn and improve over time.

They can predict maintenance needs and optimize lifting routes. This cuts downtime and saves money on repairs.

Smart features like automatic load weighing and positioning increase efficiency. They help cranes work faster and more accurately than ever before.

Frequently Asked Questions

Overhead and gantry cranes have specific regulations, safety standards, and operational requirements. These guidelines cover inspections, operator training, design considerations, and safety precautions.

What are the OSHA regulations for overhead cranes in general industry?

OSHA has rules for overhead cranes. These include load testing, regular inspections, and proper maintenance. The regulations also cover operator certification and training requirements.

Which components of cranes require special design considerations according to safety standards?

Critical crane components needing special design focus include the hoist, trolley, and bridge. Safety features like overload protection, limit switches, and emergency stop buttons are essential. The control systems and electrical components must also meet strict safety standards.

What is the mandated frequency for overhead crane inspections?

Overhead cranes need regular inspections. Daily visual checks are required before each use. Monthly inspections cover more detailed examinations of components. Annual comprehensive inspections involve thorough testing of all systems and structural elements.

What training is required for overhead crane operators to meet OSHA standards?

OSHA mandates comprehensive training for overhead crane operators. This includes classroom instruction on crane physics and safety procedures. Hands-on training with the specific equipment is also necessary. Operators must demonstrate proficiency before certification.

What safety precautions are necessary when operating a gantry crane?

Gantry crane safety involves checking the work area for obstacles. Operators must ensure proper load securement and stay within weight limits. Clear communication with ground crew is crucial. Personal protective equipment like hard hats and safety shoes is required.

How does a bridge crane operation differ from a gantry crane in terms of control methods?

Bridge cranes typically use pendant or radio controls for operation. Gantry cranes may use similar controls, but larger models often have cab-operated options. Bridge cranes move along fixed runways. Meanwhile, gantry cranes can be more mobile with wheeled bases.